Lifting & handling equipment are fundamental devices at any stage of every kind of plant.

Our added value are the freedom to select any brand at any location in the world, and the wide network of business partners who can customize or design from zero, special solutions tailored in terms of material, dimensions, construction necessary to withstand with moist severe conditions, either of usage or of environment up to the marine one, for which we can provide solutions tailored in terms of structural calculation/construction, painting and ATEX area classification up to ZONE 1, supplied along with mandatory certificates issued by the third party naval entity in charge for each project.

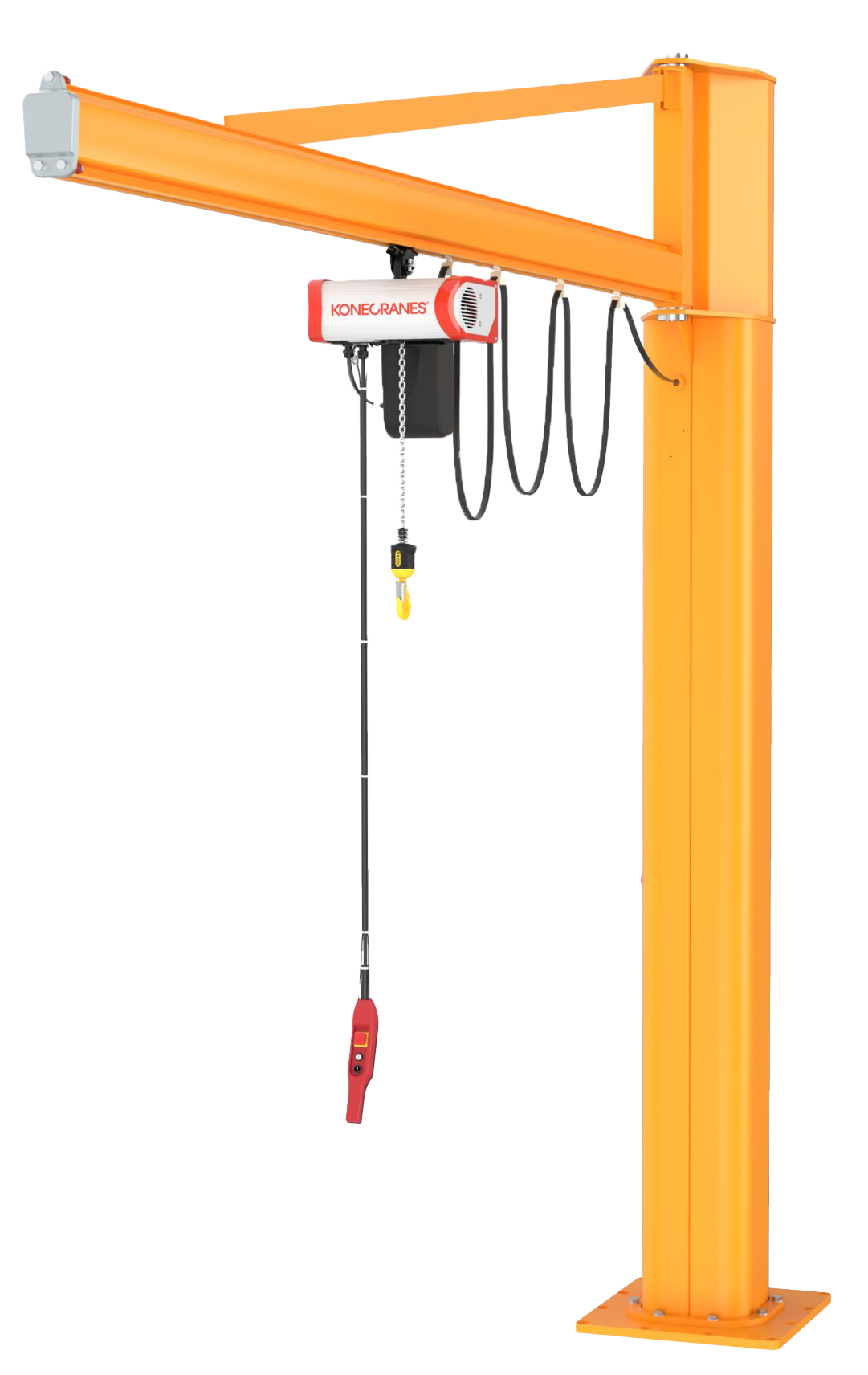

Manual and electrical JIB crane

Multifunctional lifting tongs and clamps

Electric pallet truck

Manual and electrical chain hoist from 0,5ton up to above 10ton

Manual and motorized gantry cranes

Electrical drive crane with variable wheelbase

Stackable metal container for construction site materials and equipment, available with standard dimension, material, or customizable

Electric powered counterbalance forklift trucks

Terminal tractors & shunt trucks

Heavy duty self propelled trolleys, movers and skates

Diesel powered counterbalance forklift trucks

Single girder & double girder overhead crane

Do you have a question or need specific information? Write to us and we can best advise you.

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs