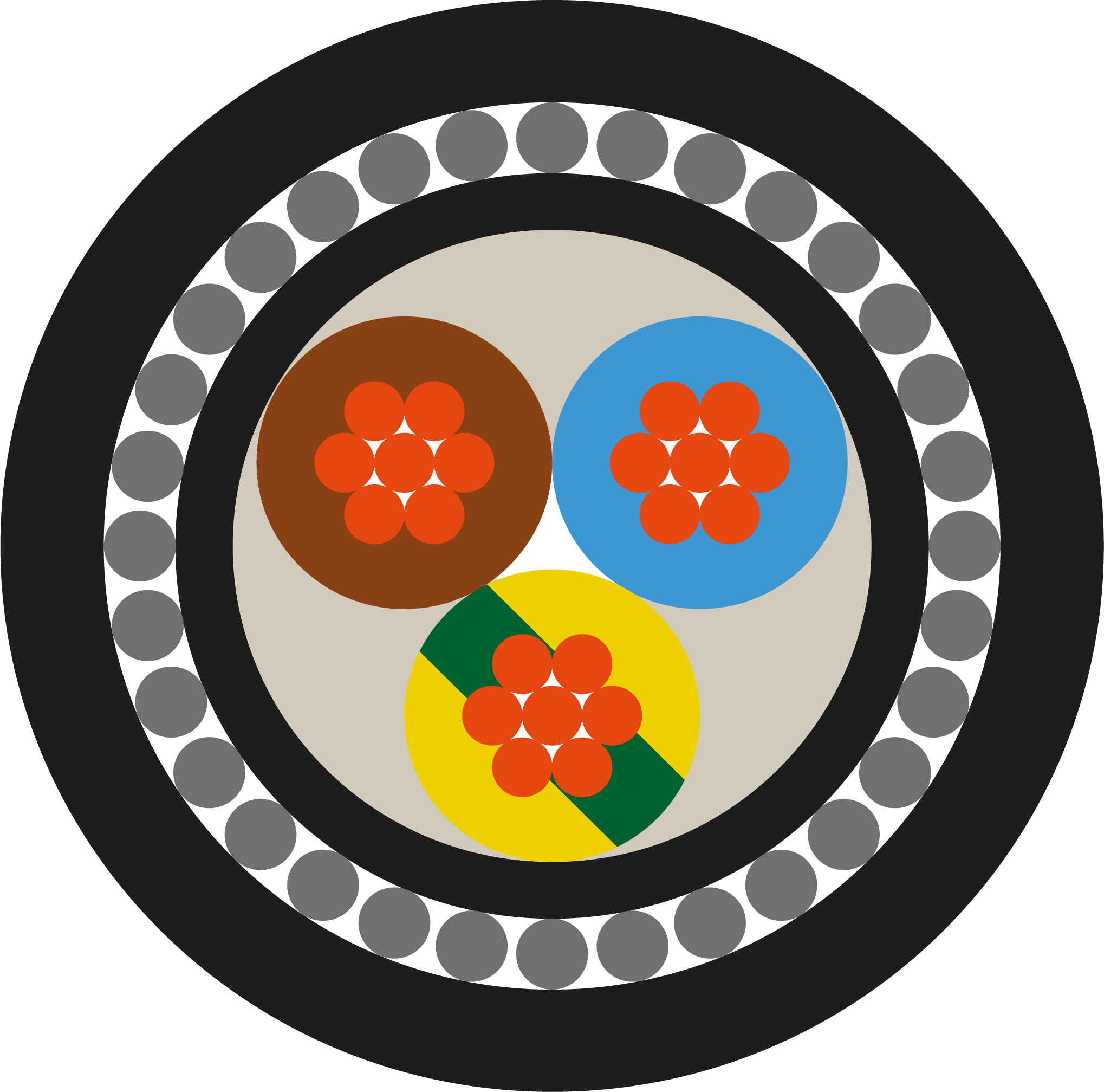

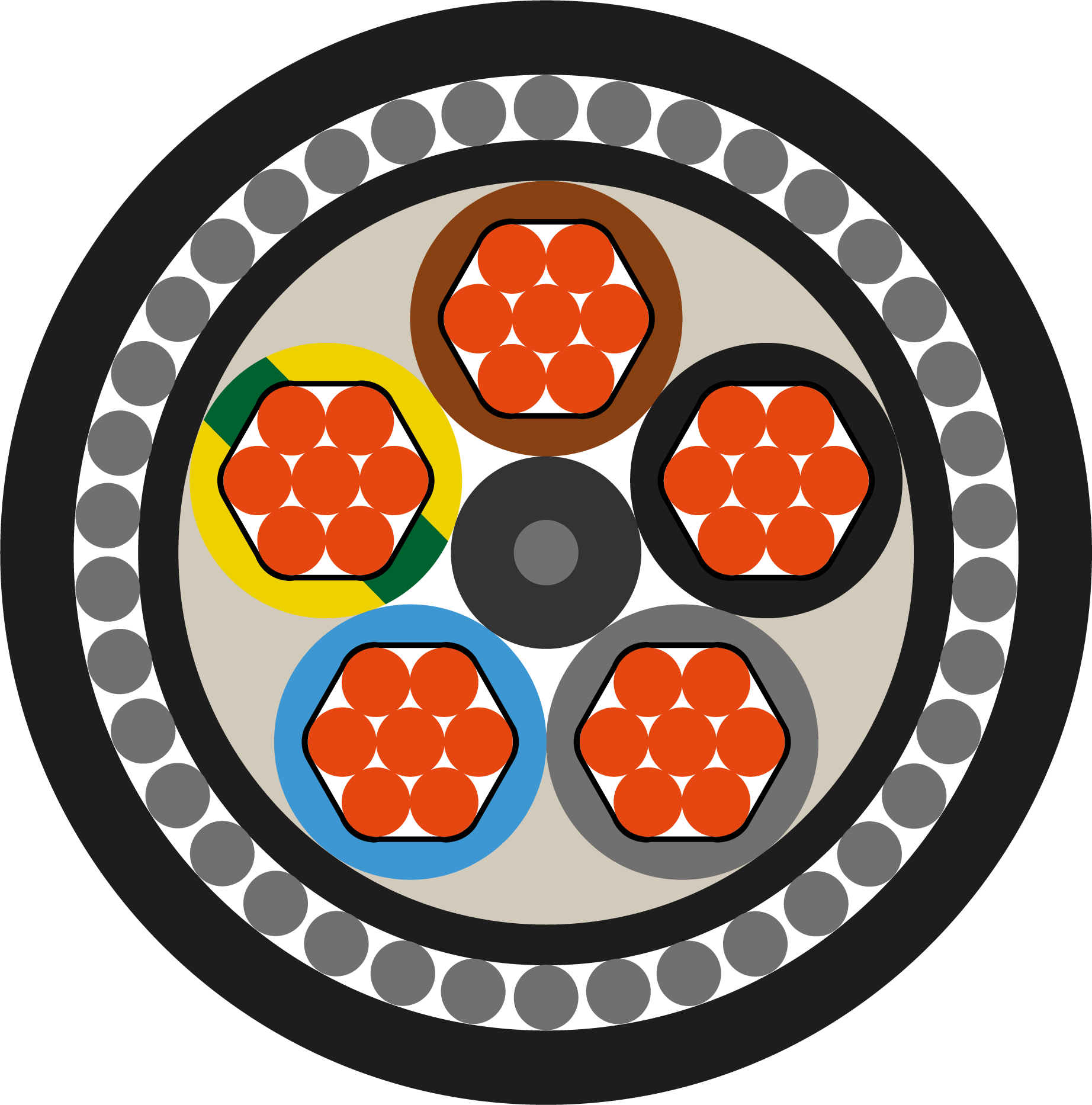

High-quality fire performance cables are engineered to maintain functionality under extreme conditions, ensuring reliable signal transmission and power supply even during fire scenarios. Designed for critical applications, these cables support emergency systems, alarms, and essential communication networks. Featuring fire-resistant insulation and robust sheathing, they undergo rigorous testing to meet stringent international standards, offering durability and safety in high-temperature and high-risk environments. Ideal for industrial, commercial, and public facilities, these fire performance cables deliver resilience and compliance for maximum protection.

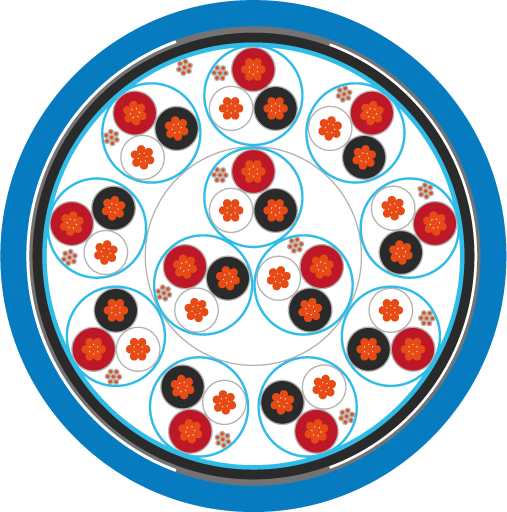

Spina Group manufactures and supplies instrumental cables for transmission of analog (4…20mA) and digital signals, interconnection of measuring and process instruments, in safety areas and in augmented and intrinsically safe environments. We also manufactur and supply thermocouple cables TX, JX, EX, KX type to be used in all conditions and in every industrial plant. Production takes place on the basis of specific contracts and the cables are carefully tested to ensure maximum performance.

Do you have a question or need specific information? Write to us and we can best advise you.

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs