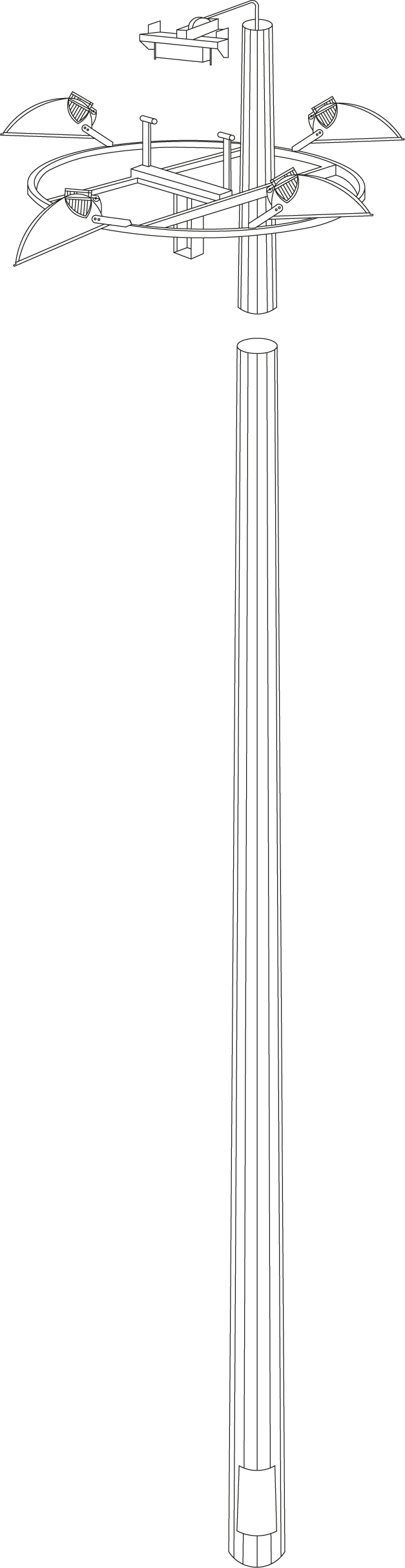

A wide range of products for industrial lighting is available, offering exceptional reliability and sustainability.

The specialized technical office creates three-dimensional renderings with virtual images featuring realistic lighting effects, delivering customized designs tailored to customer requirements for both indoor and outdoor settings.

Key application sectors include roads, construction sites, industries, power plants, and large facilities.

Spina Group offers a wide range of lighting solutions for both indoor and outdoor environments, including LED lighting fixtures, LED floodlights, LED emergency lights, LED street lighting, and LED high and low bay lights. We provide solutions for both hazardous areas and safe areas.

Need help?

Get in touch

Do you have a question or need specific information? Write to us and we can best advise you.

Request a quote

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs

Download the catalogue

Download our PDF catalog to get all the detail information related to this product category