MV/LV switchboards are designed to meet international standards and customized to client specifications. Our switchboard solutions are developed by our internal technical department, ensuring compliance with project requisitions and all relevant CEI and international standards.

We provide a full range of services, including planning, wiring, testing, packing, shipment, and detailed technical documentation. Our switchboards offer protection degrees of IP55, IP65, and IP66, ensuring reliability and safety in various industrial environments. Tailored to meet the specific needs of each project, our switchboards guarantee robust performance and long-lasting durability.

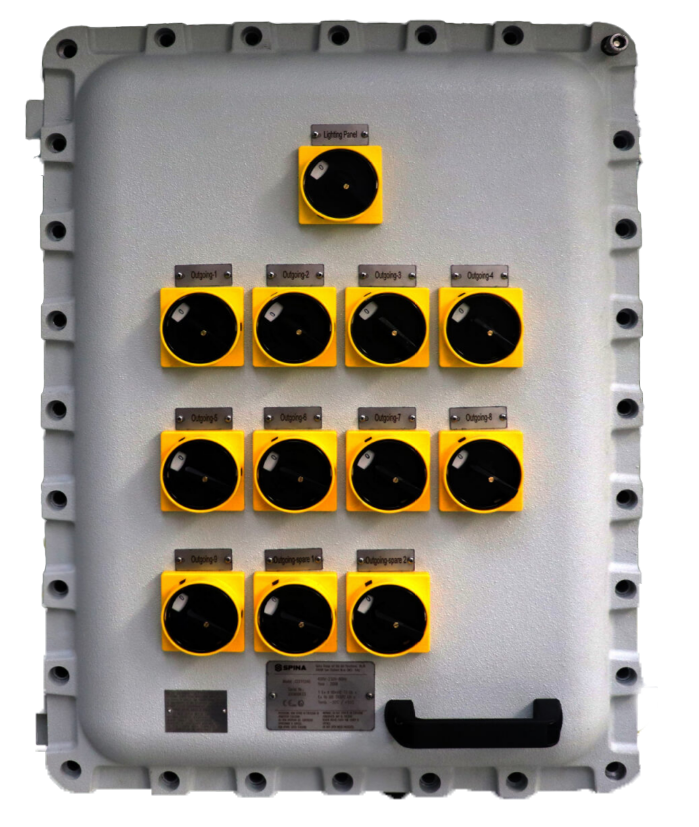

Spina Group specializes in portable field panels designed for reliable power distribution and control for industrial environments. These panels are made as stainless steel or GRP, ensuring durability and resistance to corrosion and impact.

Our portable field panels come with various configurations, featuring multiple input and output connections, in compliance with IEC, CEE standard. Teh industrial panels can support different voltage levels (typically 230V to 400V). Equipped with protective enclosures rated IP55 or IP65, they provide excellent protection against dust and water ingress, making them suitable for all conditions.

These panels are ideal for applications in sectors such as oil & gas, construction, and chemical processing, enabling safe and efficient operation of portable equipment and machinery. With integrated circuit protection and compliance with relevant safety standards, Spina Group’s portable field panels ensure high performance and reliability in the field.

Spina Group offers LV distribution boards designed using CCF and GUB enclosures, ideal for creating Ex d / Ex de switchboards in various configurations according to customer specifications. These boards are suited for applications such as lighting distribution, power distribution, heat tracing, and motor starters.

Made from copper-free aluminum, stainless steel, or GRP, they are built to withstand harsh environments. With installation areas classified as Zone 1 – 2 / 21 – 22, these distribution boards provide reliable and safe solutions for hazardous locations, ensuring compliance with all relevant standards and customer-specific project requirements.

Do you have a question or need specific information? Write to us and we can best advise you.

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs