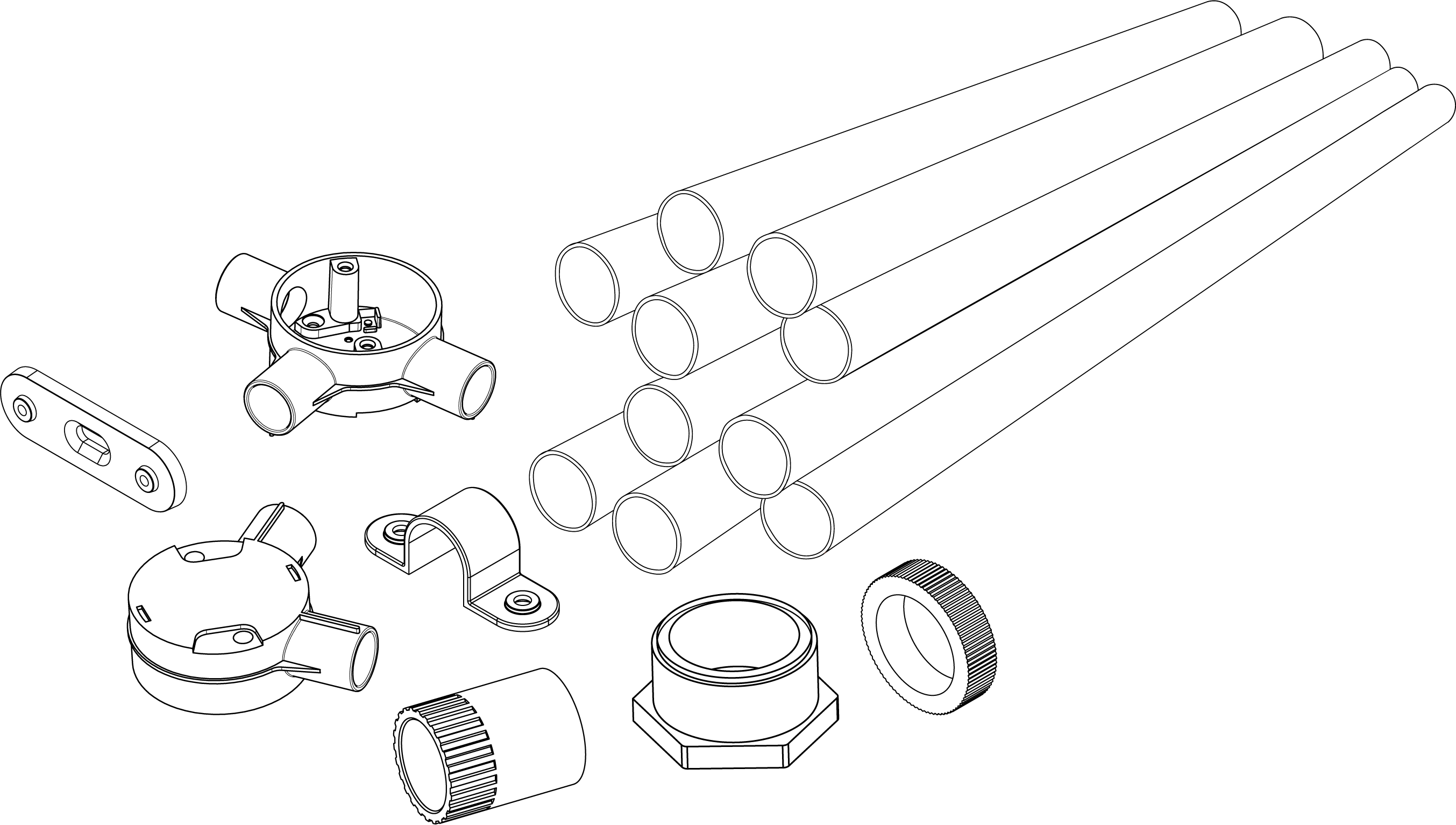

Spina Group offers a comprehensive range of conduits designed for high-performance electrical installations, adhering to applicable standards based on project needs. We supply rigid conduits, threaded conduits, and related accessories, ensuring optimal mechanical protection and electromagnetic shielding for electrical conductors and cables.

These conduits are essential in industrial settings, particularly in environments subject to vibration, such as motors, pumps, and pendant lighting. Additionally, they are ideal for installations in hazardous areas, meeting strict standards like ANSI C80.1, UL 6, and NEC requirements.

Available in materials such as hot-dip galvanized steel, aluminum, and stainless steel, our conduits ensure durability and reliability even in the most demanding applications, both onshore and offshore.

Our threaded electrical conduits, made from hot-dip galvanized steel (or available in aluminum, AISI 304, and AISI 316 stainless steel upon request), meet ANSI C80.1 and UL 6 standards. Designed for high mechanical protection and cable routing, they comply with NEC Art. 344 for use in Class I, II, and III hazardous environments. These conduits also provide electromagnetic shielding and interference reduction, ensuring safe and reliable installations in demanding industrial settings.

Need help?

Get in touch

Do you have a question or need specific information? Write to us and we can best advise you.

Request a quote

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs

Download the catalogue

Download our PDF catalog to get all the detail information related to this product category