Spina Group offers a complete range of cable tray accessories and fixing components designed to simplify installation and ensure maximum stability for electrical and instrumentation systems.

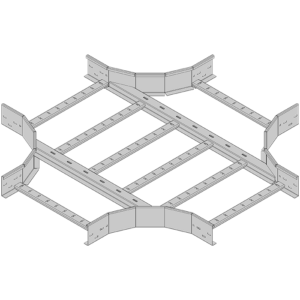

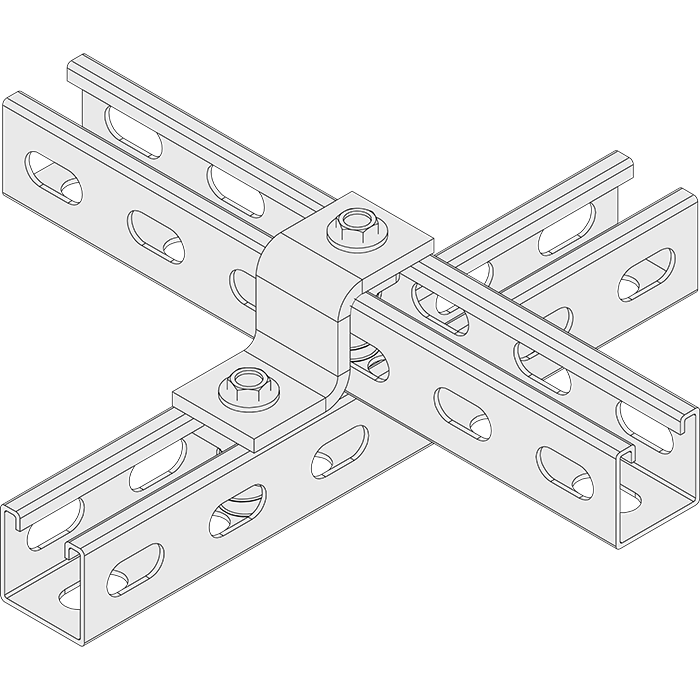

Our range includes cable ladder accessories, joints, and fixing brackets that guarantee safe and quick assembly for all cable tray types, from perforated to ladder and wire mesh.

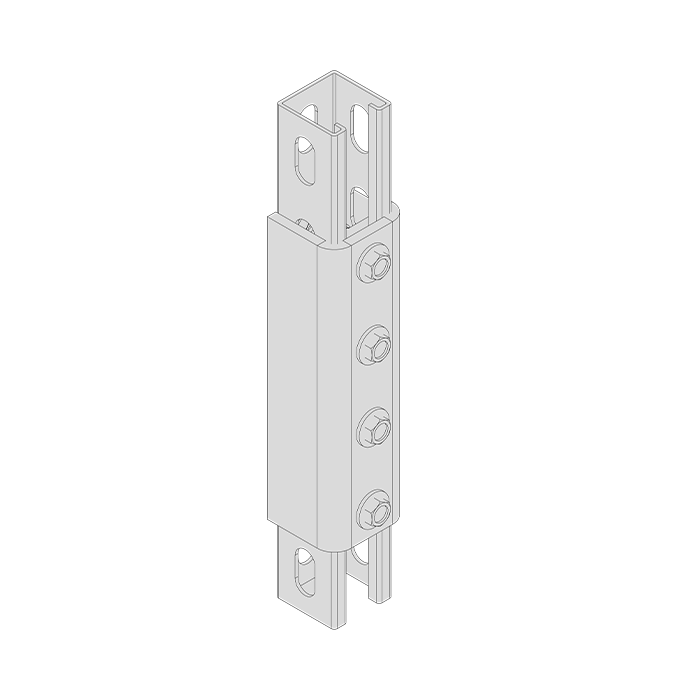

Among our most requested solutions are cable tray joints and expansion joints, which allow flexibility and compensate for thermal expansion, maintaining the alignment and mechanical strength of the system even under temperature variations.

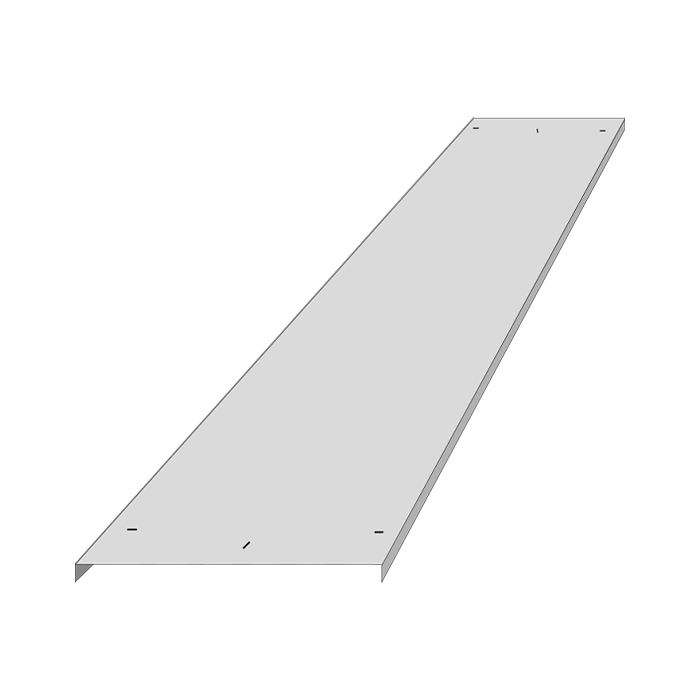

The accessory line also includes separators, end edges, wall supports, and floor fixings, available in Hot-Dip Galvanised (HDG), stainless steel, and aluminium to ensure compatibility with all Spina Group cable tray systems.

Every fixing accessory is engineered according to European standards, offering durability, corrosion resistance, and ease of installation — the ideal choice for industrial and infrastructure applications.